August 2024 - August 2025:

Mechanical Engineering Internship working on self-check-out hardware

Skills:

Solidworks, PDM, Documentation, Compliance, DFM, ESD Testing

Project Overview

The MxP Vision Kiosk is Toshiba’s latest self-checkout system, consisting of over 800 mechanical and electronic components. During my internship, I contributed to the mechanical design, prototyping, and validation of key subsystems. My work focused on improving manufacturability, ensuring electrostatic discharge (ESD) compliance, and overall defect resolution.

Manual Reset Button

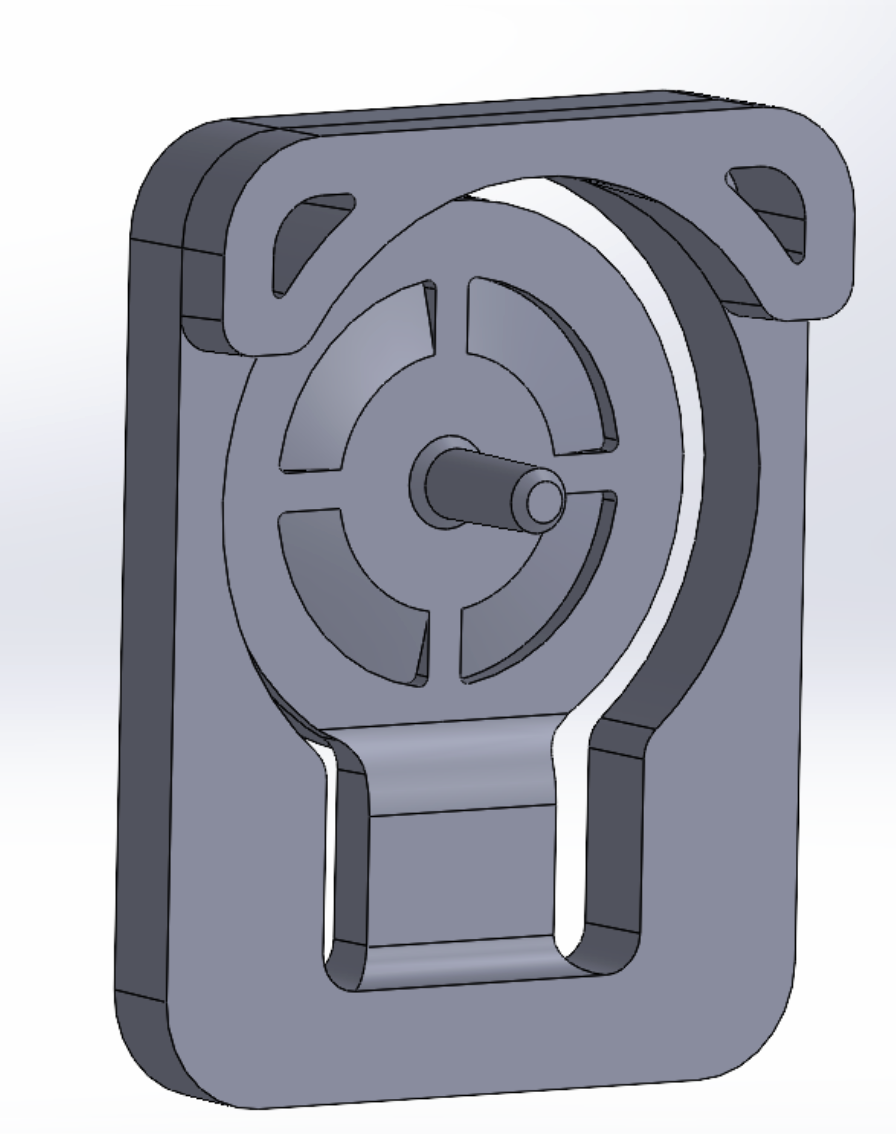

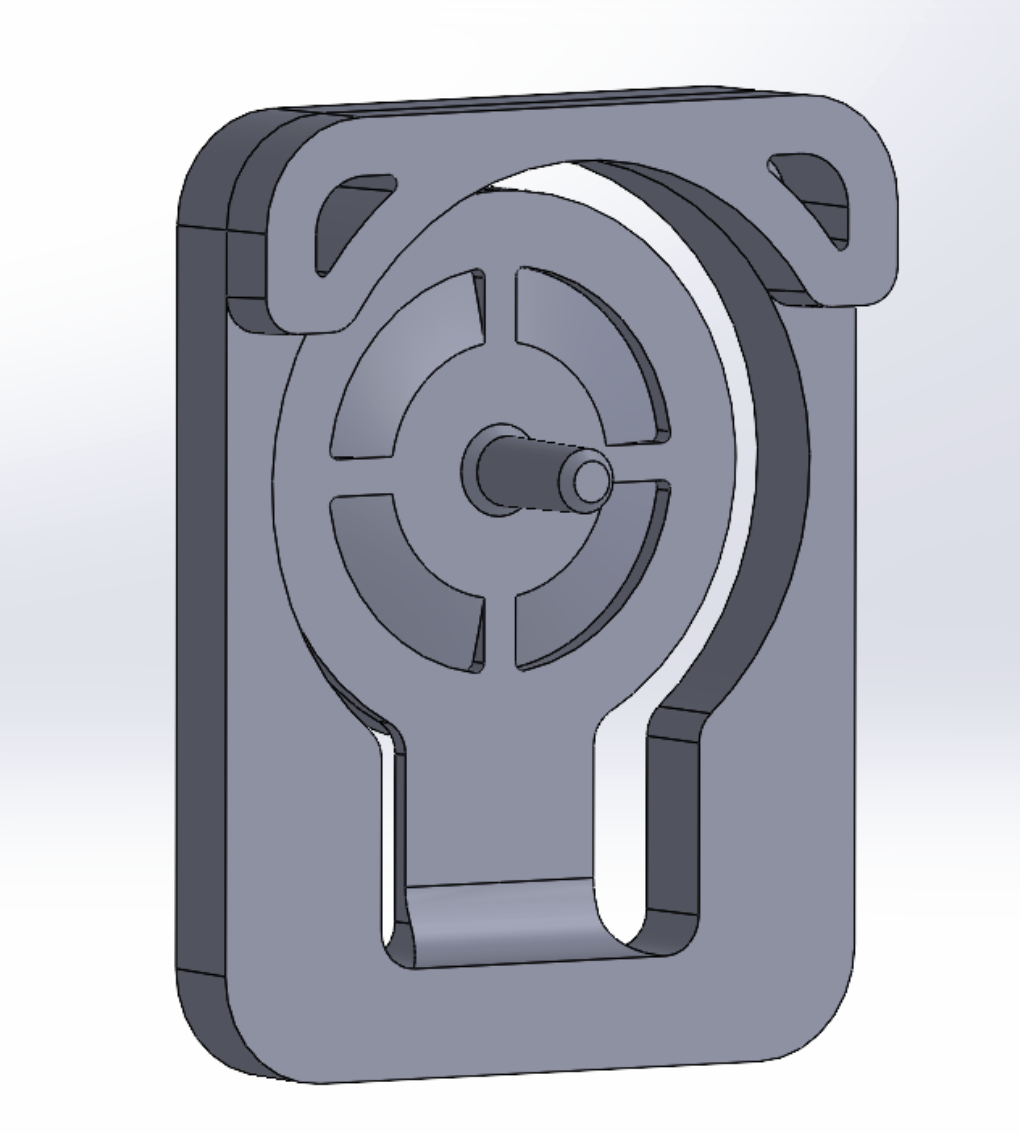

In the self-checkout computer, the manual reset pin failed to work as intended. Through testing, we determined that the pin throw was too short, and pressing the button did not trigger a reset.

I redesigned the button in SolidWorks to extend its actuation and ensure reliable engagement with the reset pin. I prototyped iterations on in-house FDM printers, updated the engineering drawings, and submitted the design for manufacturer tooling, which was approved.

Key Design Changes:

Reduced 2 mm from the pin arm to improve clearance.

Reduced 2 mm from the overall width to fit within the housing.

To prevent a 3-week launch delay while tooling was completed, I sourced Nylon 12 multijet parts from Protolabs for the first 30 units. I coordinated with suppliers to order die-cut adhesive, manually applied it to each part, and assembled them onto the systems. This temporary solution enabled on-time shipment of the first production units while the tooled version moved forward.

Resigned Reset Button with Longer Pin Throw

Button Iterations: FDM on Top Row, Protolabs on Bottom Row

ESD Compliance Testing

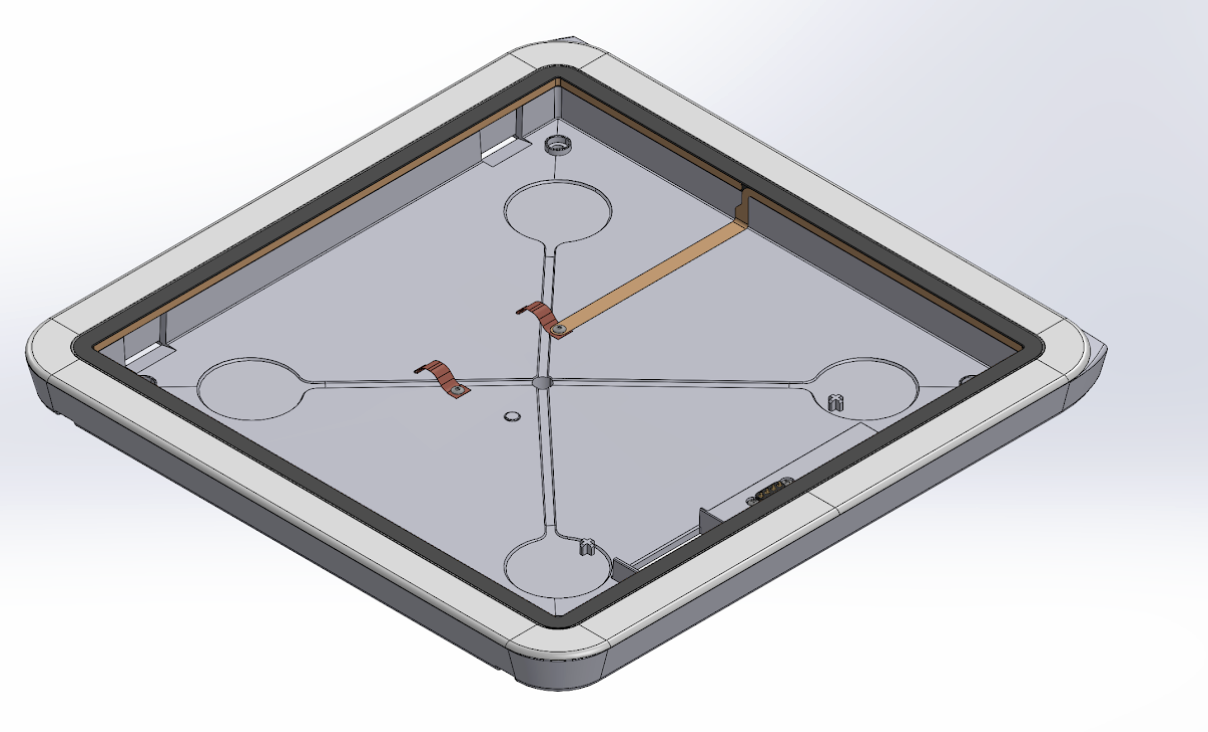

To ensure the kiosks met IEC electrostatic discharge (ESD) standards, I ran compliance tests and diagnosed failures where static discharge disrupted the touch interfaces.

I prototyped and evaluated four different grounding solutions:

Spring finger inside the scale pad to ground the internal circuit boards.

Spring finger on the ring light that contacted the metal scale pad housing.

Copper tape wrapped around the ring light, grounded to the chassis.

Impedance beads added to the pogo pin connection on the ring light.

Each concept was tested using an ESD gun at controlled voltages to measure effectiveness. I documented performance, compared trade-offs, and reported results to the engineering team. This work directly contributed to refining the hardware design so the system could pass ESD compliance and move forward to production.

Final Ring Light Grounding Solution

Test Result Documentation

ESD Testing on MxP Vision Kiosk

Final Solution & Testing

After evaluating multiple grounding strategies, the most reliable solution combined a spring finger in the scale pad with improved firmware — eliminating the need for copper tape and ensuring consistent grounding. This design passed IEC air gap and contact discharge tests up to ±15 kV, meeting both industry and TGCS standards.

To validate performance, I built a tracking spreadsheet where I logged each test run, including voltage, polarity, number of strikes, pass/fail results, recovery times, and comments. This structured data allowed the team to quickly see trends, identify weak points, and converge on a robust solution.

Learnings: I gained firsthand experience in running compliance tests, documenting results in a way that supported decision-making, and iterating between hardware changes and firmware updates. This reinforced the importance of system-level grounding strategies and the value of organized, transparent reporting when collaborating across engineering teams.