Fall 2024 - Spring 2025: Senior Design Client Project

Skills: CAD (Solidworks), Electronics, Waterproofing

Project Overview

Scuba divers currently estimate underwater visibility, but no reliable device exists to measure it. Our team partnered with Garmin to design a prototype that quantifies visibility using turbidity measurements and wirelessly displays the data.

My role: Housing design, waterproofing, testing

Design Criteria:

Waterproof & Pressure-Resistant: Withstand 60 ft depth (IP68) with 1.5× safety factor, ensuring safe operation.

Accurate & Usable: Provide repeatable visibility data within ±10 ft, in a compact, easy-to-mount form with a simple UI.

Reliable & Sustainable: ≥1.5 hr battery life (achieved >8 hrs), shock/drop safe, and designed to minimize ocean pollution.

Key Components

Our device integrated several critical modules:

ESP32 + SD Card: Microcontroller for data logging and wireless upload.

Turbidity Sensor: Captures visibility readings underwater.

Induction Charging Coil: Enables wireless charging to avoid openings in the housing.

Velcro + D-Ring Attachment: Provides a simple, reliable way for divers to mount the device to their BCD.

Housing & Waterproofing Challenge:

Knowing these four components would define our design, I modeled a compact SolidWorks enclosure that fit them securely while withstanding dive pressures. By combining SLS Nylon 12, a marine-grade epoxy coating, and a custom silicone gasket, I developed a waterproof housing proven to be pressure-resistant to 3-bar (≈60 ft).

D-Ring and Velcro

Turbidity Sensor

Induction Charging

ESP32 and SD Card

Housing Design

This image shows the progression of housing prototypes, from the earliest designs (top left) to the most recent (bottom right). Early versions tested the general form and component layout, while later designs refined gasket grooves, fastener placement, material selection, and internal mounts to ensure a secure fit and seal. The final housing is shown below.

Final Housing Design:

Flat Gasket Gland & compression V-groove

Nylon12 SLS 3D Printed

Internal Mounts for electronics integration

Final Housing Design

Housing Design Iteration

Waterproofing

Analysis

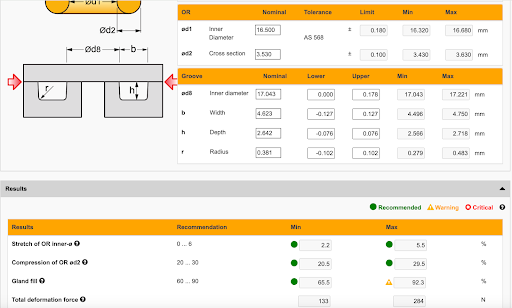

Gasket Analysis: For the gasket analysis of this device, the material used is Silicone 50A, which is a general-purpose rubber that is compatible with solvents and other soft chemicals. Using this information and the required dimensions according to Parker Hannifin, a range of various constraints was determined.

Parker Analysis

Testing

To ensure our housing would actually survive underwater, we ran a series of controlled tests focused on how the seal and fasteners performed under pressure. We tried different gasket geometries, screw types, and screw placements to see which combination would give the most reliable waterproofing.

Seal & Fastener Experiments

Protocol: 3-bar (≈60 ft) hyperbaric tests, 1-hr submersion, water-indication stickers, controlled torque.

Seal geometry:

Face seal vs. flat gasket w/ V-ridge.

Result: Flat silicone 50A gasket + V-ridge delivered more uniform compression and repeatable, leak-free seals.

Screw head type:

Socket head vs. countersunk.

Result: Socket head (with washers) avoided local wedging/stress and reduced seepage observed with countersunk heads.

Screw location:

Inside the gasket path vs. outside.

Result: Screws inside created capillary leak paths; relocating outside the seal eliminated ingress.

FEA Analysis: Using FEA, the team determined that the yield strength was 6.000e+07 Pa. Thus, the box is predicted to withstand a pressure of 3.0 bar, or 300,000 Pa, at 60 ft underwater.

FEA Analysis

First Waterproof Prototype

Finding the Leak Path

Final Design

The final design brought together all of our testing and iteration into a compact, diver-friendly device. The waterproof housing, sealed with a silicone gasket and secured by socket head screws, kept the electronics safe down to 60 ft. Simple piezo switches and LED indicators gave divers clear feedback, while the Velcro strap made it easy to mount on a BCD. See how it works below.